The first planes often crashed. The first boilers heated houses but often exploded. The first electric toasters burned bread and sometimes the cook. But eventually these technologies were accepted, and they caught on widely.

The history of technological advances suggests that industries, regulators and customers accept a new technology only once it establishes a baseline of trustworthiness. But who determines what’s trustworthy? How is that gauged?

To inform such decisions, people need an independent source of knowledge about what’s safe, dependable and worthy of confidence. One such source—known by the holographic UL stickers on your extension cords or the stamps on your appliances—is Underwriters Laboratories.

Since its founding in 1894, the organization has been at the forefront of bringing safety to life through science, essentially creating the field known as safety science. Through more than 130 years, it has developed standards and safety tests for a bewildering array of consumer products and services—and paved the way for our trust in many technologies we take for granted today.

But now the world is changing. New technologies are entering the marketplace faster than ever before, making the pace of testing that much faster—and that much more urgent. After its invention in the 1870s, the telephone took 75 years to reach 100 million users worldwide. Social platforms and other online services can now accrue hundreds of millions of users in a matter of months. A convincing deepfake of a politician calling for violence, sent to hundreds of millions, can be just as deadly as a badly wired home appliance.

To meet this pivotal moment, the entity once known as Underwriters Laboratories has transformed itself. In 2022 it rebranded and restructured, supercharging its research efforts with $1.8 billion in the process. UL Solutions, a for-profit business, partners with companies to test, inspect and certify consumer products. UL Standards & Engagement, a nonprofit organization, develops rigorous safety standards and drives safety advocacy campaigns. UL Research Institutes (ULRI), an affiliated nonprofit, does independent research into ongoing and emerging safety risks.

In our globalized, interconnected world, understanding safety risks means considering all of society, notes Christopher J. Cramer, interim president and chief research officer at ULRI. “The definition of safety has broadened.”

ULRI has set ambitious goals that the organization considers grand challenges for the planet: building resilience for a sustainable future; advancing individual and societal health in the 21st century; and promoting safety at the human-digital interface. Building a future that is simultaneously safer and more sustainable will require addressing complex issues, in fast-moving fields ranging from digital security to environmental health.

“These are big problems,” says Cramer. “They’re not going away tomorrow.”

The city unburnable

These goals trace back to Underwriters Laboratories’ founding at the end of the 19th century and an event that was a great harbinger of economic change: the Chicago World’s Fair of 1893.

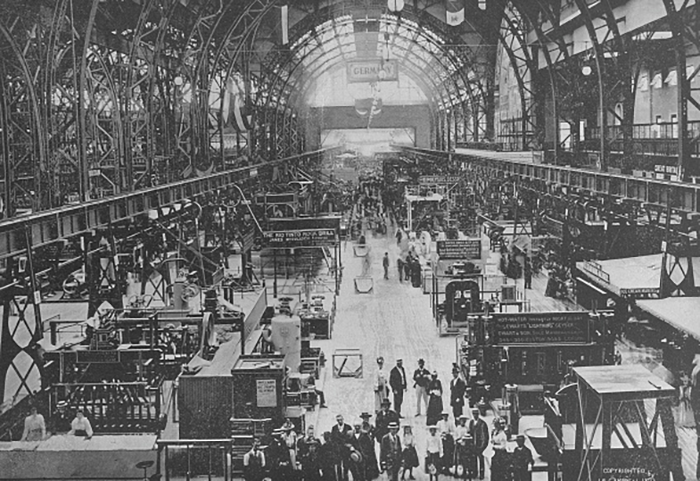

With the Industrial Revolution at full steam, countries around the world were changing rapidly—and competing to showcase the latest technological wonders. The growing city of Chicago won 1893’s bid. Across 686 acres on the city’s south side, architects Daniel Burnham and John Root built a complex so resplendent, it became known as the White City. The area contained hundreds of buildings, 57 miles of roadway, and a world first in urban design: miles of electrical wires and connections snaking beneath the city’s jute and plaster facades.

The novelty—and flammability—of the fair’s electrified buildings presented substantial fire risks. Chicago was also haunted by a grim specter: the Great Fire of 1871, a conflagration that had killed 300 people and destroyed more than 17,000 buildings. To better understand the electrical safety hazards of the White City’s wiring, a young, MIT-trained engineer named William Henry Merrill, Jr., was recruited.

Blazes still broke out: 17 people died at the fair in July 1893 when a poorly designed smokestack at a large refrigerated building caught fire. But electrical fires were kept to a minimum, and Merrill had demonstrated his mettle. In so doing, the fair provided Merrill with the opening—and the opportunity—to test the safety of new electrical technologies, in experiments funded by insurance underwriters and equipment manufacturers. The nonprofit Underwriters Laboratories was born.

Underwriters Laboratories was founded in 1894 by engineer William Henry Merrill, Jr., after his work at the Chicago World’s Fair and its exhibit buildings.

Museum of Science and Industry, Chicago/Getty Images

In 1894 UL set up shop on the third floor of a fire patrol station on Chicago’s Monroe Street. Its first test: an asbestos-based paper that claimed to be both fireproof and nonabsorbent (the material failed on the latter point, according to Merrill). Within a year, Merrill and his small team completed 75 tests on a budget of $3,000, evaluating various electrical products, automatic sprinklers and devices that burned a newfangled fuel called acetylene.

Over the next three decades, UL grew significantly and expanded to a 55,000-square-foot complex on Chicago’s East Ohio Street, a brick and terracotta fortress that some employees nicknamed “The City Unburnable.” The three-story building’s test furnaces roared constantly, as engineers devised ever more ingenious ways to subject products to hellish testing conditions. In one eye-catching 1923 experiment, engineers baked a safe until it was red-hot and then dropped it from a 30-foot-tall crane onto a pile of bricks, to simulate whether the safe could protect its contents through a fiery building collapse. Along the way, the laboratory picked up its oldest motto: Ignis Servus Non Dominus. Fire is our servant—not our master.

UL engineers also tested plenty of products that didn’t meet the mark. In an August 1903 article, a reporter for Scientific American recounted the story of a man who visited UL’s laboratory and challenged its engineers to find any fault with his homemade, acetylene-burning generator. “A very moderate test sufficed to blow the apparatus to pieces and cover the inventor with plaster and fragments,” the author dryly noted. “He was taken out into the yard and put under a hose, after which he went away convinced of his error.”

As technologies and consumer trends changed, the number of product categories that UL tested ballooned: home radios, seatbelts, microwave ovens, personal computers. And as its remit grew and grew, UL often introduced voluntary safety standards that were years—and in some cases decades—ahead of government action.

In 1915, with more than two million cars on U.S. roads, UL established a department focusing on automobiles. It began testing car parts the following year—and has a claim to designing one of the world’s first automotive crash test dummies. UL’s work predated the first major U.S. car safety law, the National Traffic and Motor Vehicle Safety Act of 1966, by more than 50 years. From 1921 to 1925, UL ran the first national organization anywhere that certified airplanes’ airworthiness and kept records on pilots’ qualifications and training. The organization’s safety efforts laid the groundwork for the passage of the Air Commerce Act of 1926, giving rise to what is now the Federal Aviation Administration (FAA).

When it comes to airplane and automobile safety, “everyone thinks, ‘the federal government takes care of that.’ Well, yes, they do now, but not always,” says Alan Akers, ULRI’s lead archivist. “You see time and time again where we’ve been able to fill that void and help advance the cause of safety science and public safety.”

The institutes advance these causes by conducting research that’s independent of outside influences and grounded in rigorous science, then sharing it with professionals and institutions worldwide. ULRI also cultivates future scientific thinkers by translating its leading-edge research into educational resources and programming focused on real-world safety science. ULRI’s Office of Research Experiences & Education (OREE) creates open-access learning materials for middle and high schools, as well as workforce and professional development programs. OREE Senior Director Kelly Keena says the goal is threefold: “Build access. Build resources. Build the field. Through each of these priorities, our office is preparing future safety scientists.”

Safety-science researchers focus on fast-moving fields such as digital security.

Kindamorphic/E+/Getty Images

Taming digital technology

The experts who make up ULRI’s research corps know what it means to lead on emerging safety concerns. Here’s how Jill Crisman, vice president and executive director of ULRI’s Digital Safety Research Institute (DSRI), frames that quest for safety. How can Internet service providers build in defenses “against cyberattacks, scams, frauds and malicious use? How do we make sure that algorithms protect individuals’ rights and society’s integrity?” As safety scientists in this century, she says, “We have to be checking for these things.”

DSRI’s subject-matter experts are already laying the groundwork. While pursuing a Ph.D. at Oregon State University, Sean McGregor focused on fire safety and built a computer model that used artificial-intelligence techniques to forecast how forests would respond to a given wildfire policy up to a century into the future. Along the way, McGregor found himself humbled—and unnerved—by the power of the AI tools he was using and creating. As a result, McGregor switched his focus to the safety of AI systems themselves. Now he’s the director of advanced test research at DSRI, where he and his colleagues are racing to build the tools and testing procedures that can help ensure—and define—safety at the human-digital interface.

More broadly, standards, regulations, established tests and trustworthy certification all will be essential, Crisman says. But the need for such requirements creates another question, she notes: “Who is going to actually certify that companies are compliant with these standards?”

As climate change brings more heat and droughts, wildfire dangers are rising.

Andrew Merry/Moment/Getty Images

Fire’s root causes

Though all aspects of ULRI’s work are at the leading edge of safety, some of its work would also be surprisingly familiar to a time-traveling William Henry Merrill, Jr. After all, UL was founded to study electrification and conflagration. Both are still at the center of modern safety science.

At the organization’s Fire Safety Research Institute (FSRI), researchers are using revolutionary methods to analyze fire dynamics, how fire spreads from structure to structure, and the safety risks that firefighters face. Now, FSRI is focusing on fires that break out along what are known as wildland-urban interfaces, where human structures mix with undeveloped wilderness. Nearly a third of U.S. homes—more than 44 million in all—stand in these areas, which are fast becoming the front lines of many modern wildfires, especially as climate change has increased the frequency of extreme heat events and droughts in some regions of the U.S.

One sobering example of these blazes’ danger occurred in August 2023, when a series of wildfires on the Hawaiian island of Maui swept through the community of Lahaina, killing more than 100 people and destroying many buildings.

Within days, Hawaii’s attorney general selected FSRI to analyze the fire’s root causes and provide recommendations to lessen the risk of similar disasters. Since then, FSRI has released a three-part report on the Lahaina fire, including a 518-page analysis published in September 2024. FSRI experts concluded that a variety of factors—including widespread complacency in the face of wildfire risk, underinvestment in infrastructure and communication breakdowns—combined to let the fire spread rapidly while stymieing evacuation efforts.

“We’ve got to learn from this event,” says Steve Kerber, FSRI vice president and executive director. “There are other places in the U.S. that have the same symptoms, and something can be done now to prevent a catastrophic loss.”

Clean energy safeguards

Other new fire risks have been linked to emerging technologies. For example, scientists at the organization’s Electrochemical Safety Research Institute (ESRI) are also examining the safety risks of today’s fastest-scaling clean energy technologies, such as lithium-ion batteries.

Since entering the commercial market in the 1990s, these batteries have seen meteoric uptake in everything from electric vehicles to large-scale energy storage for power grids. And for good reason: Lithium-ion batteries don’t degrade much with each charge cycle, they self-discharge slowly, and they pack a lot of energy storage into a small unit.

But like all technologies, lithium-ion batteries can also pose some safety challenges. “Associated with this high energy density is the potential for lithium-ion cells to undergo catastrophic failures that can generate fire and toxic gases when they fail to be designed, manufactured, charged or used correctly,” Judy Jeevarajan, ESRI’s vice president and executive director, told a House of Representatives committee in February 2024.

Today, not every product that uses lithium-ion batteries is designed to prioritize emergency responses to battery fires. The batteries in many current electric vehicles are built into the vehicles’ undersides, in a well-sealed container designed to keep water out. This is meant to keep the car’s center of gravity low and protect the battery from water. But if an electric car catches fire, firefighters may have to roll it over to access its underbelly—if they can identify that the car is electric at all. At present, the U.S. doesn’t have regulations that require consistency in labeling a vehicle as gas, hybrid or fully electric.

The materials of tomorrow

The work of ULRI makes one thing clear: In the world of safety, everything is now interconnected. Dangers in one domain may multiply across others. Yesterday’s safety solution may pose risks now and in the future. The more researchers can understand a product’s full safety risks across its entire life cycle, the more health can be safeguarded at both the individual and the societal level.

Firefighting foams illustrate the challenge. For decades, foams used to cool and suppress fires relied on compounds called per- and polyfluoroalkyl substances (PFAS). After decades of buildup and use, an estimated 97 percent of Americans have traces of these “forever chemicals” in their body. And now scientists know that they can cause a litany of health issues.

In partnership with Emory University’s Rollins School of Public Health, ULRI’s Chemical Insights Research Institute (CIRI), which evaluates the health impacts of chemicals in everyday products, has been working on a multiphase study of PFAS’s presence in consumer textiles, with the goal of better understanding how the chemicals enter the body. “Some data suggest that fetal development and cognitive capacity of young children may be altered,” says Marilyn Black, CIRI’s executive director, emerita.

Climate change itself poses enormous health risks: from individual exposure to heatstroke or illnesses borne by mosquitoes, to the societal calamities dealt by extreme weather events. Transitioning off fossil fuels is an imperative—and will require one of the biggest, fastest technological transitions in human history.

So to make the future safer, ULRI orients its research toward invention. With its new Materials Discovery Research Institute (MDRI), founded in September 2022, the nonprofit hopes to accelerate the discovery of materials that can contribute to the fast-moving climate transition.

“I would call it ecoremediation,” says Stuart Miller, MDRI’s vice president and executive director. “One of the things that we’ve seen over the past 100 years is that energy storage and generation … really raises classes of individuals out of poverty to give them a better standard of living.”

In March 2024 MDRI entered a four-year partnership with Scotland’s University of St. Andrews to search for new types of highly porous compounds called zeolites, which could help remove warming greenhouse gases from the atmosphere or pull water vapor from the air to make potable water. In September 2024 the institute launched an advanced materials science laboratory in Skokie, Illinois, that will heavily rely on automated instruments to get experimental results much faster.

Reinventing safety science

This kind of forward-thinking approach defines the future of safety science—and the future of ULRI today. Cramer, ULRI’s interim president, notes that from the early days of Underwriters Laboratories, the mission was largely one responding to the marketplace: identifying and mitigating risks in products that were already on the shelves or were making their way soon.

Now ULRI has the mindset, resources and research capacity to reduce risks before they arise. “Instead of just figuring out how to make lithium-ion batteries safer, which is important, what about creating a different battery chemistry?” Cramer says. “We’re in that discovery mode—that innovation mode.”

But for all the change that ULRI represents, the story of the institutes’ work is also one of continuity, according to Akers, the archivist. The organization remains rooted in its founder’s ideals: a commitment to a safer world for all, and relentless zeal to meet the moment.

“The specifics of the time are just different” than 130-some years ago, Akers concludes. “Our DNA is the same.”

Explore UL Research Institutes’ safety-science research initiatives.